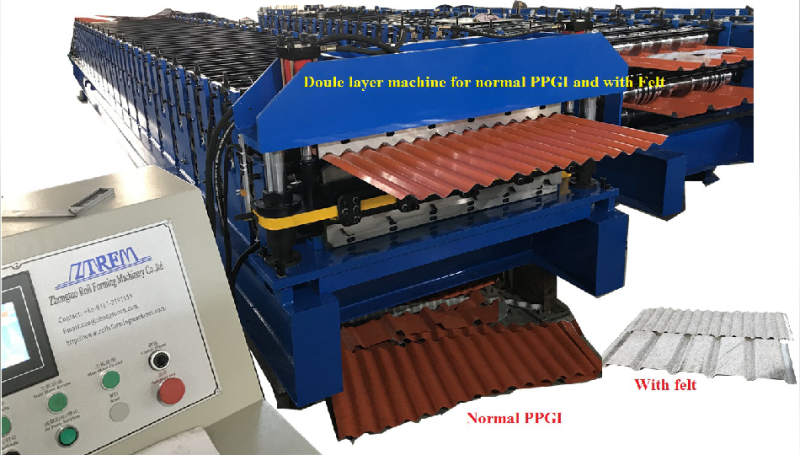

Anti-Condensation Roofing Sheets rolling forming machine

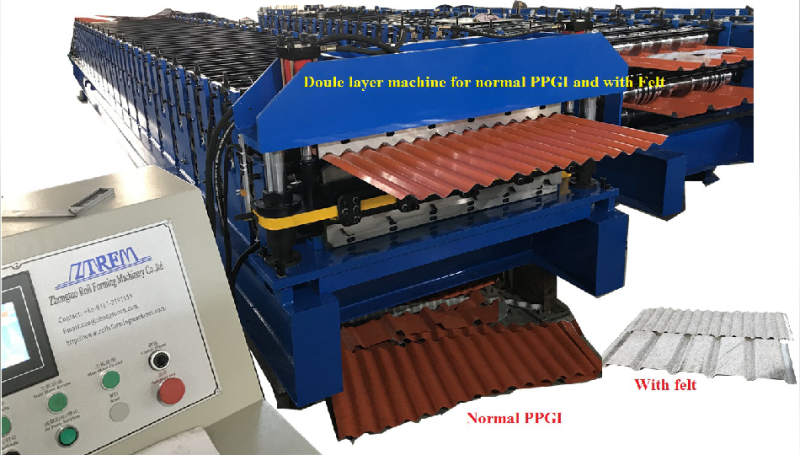

Anti-Condensation Roofing Sheets rolling forming machine is designed to make the metal roofing sheets with the anti-condensation function in batch fully automatically.

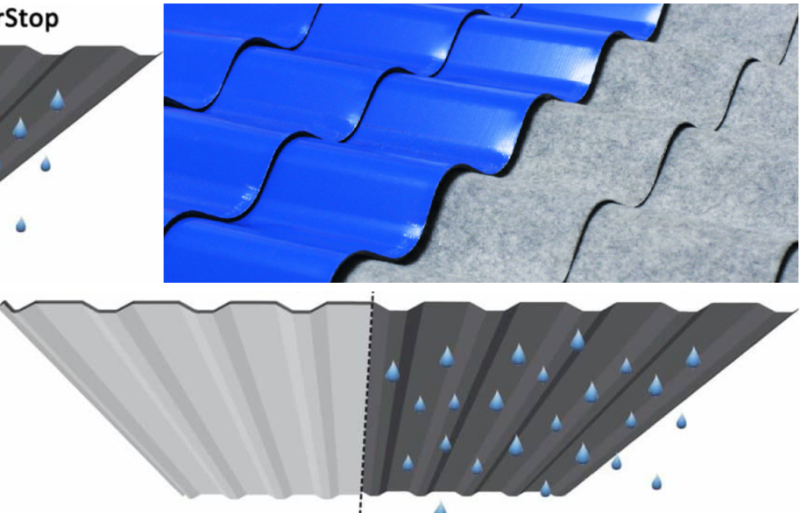

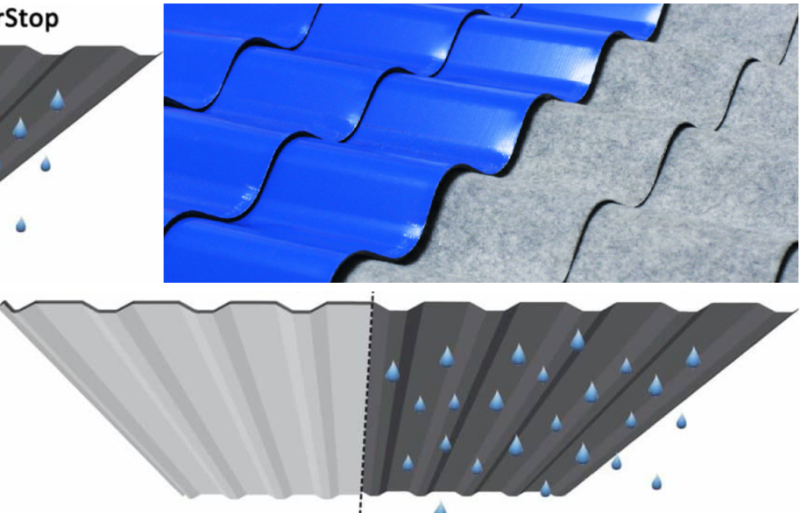

Despite the quick installation and superb longevity offered by most metal roofing sheets, they are vulnerable to condensation build-up and water droplets forming.

Over time this can result in dampness, black mould, unpleasant odors, and decaying framework. As a result, any belongings being stored beneath will soon become

damaged and the structure can even become unstable.

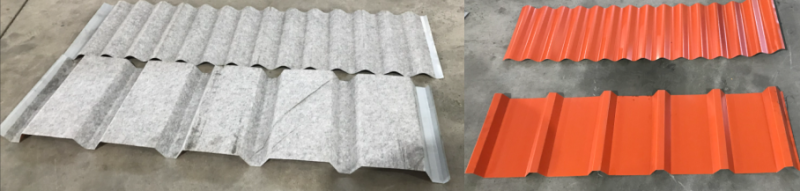

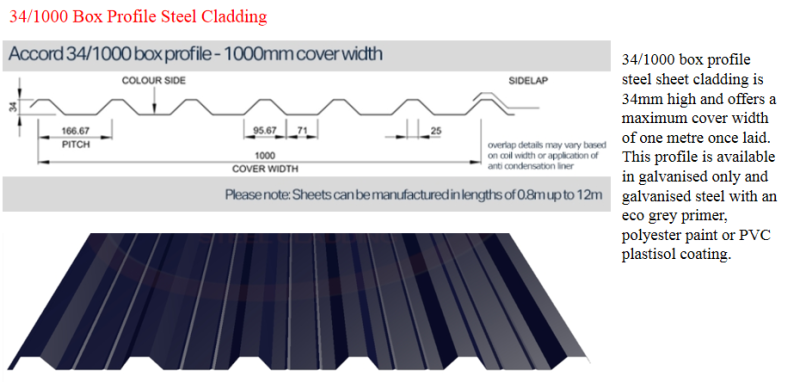

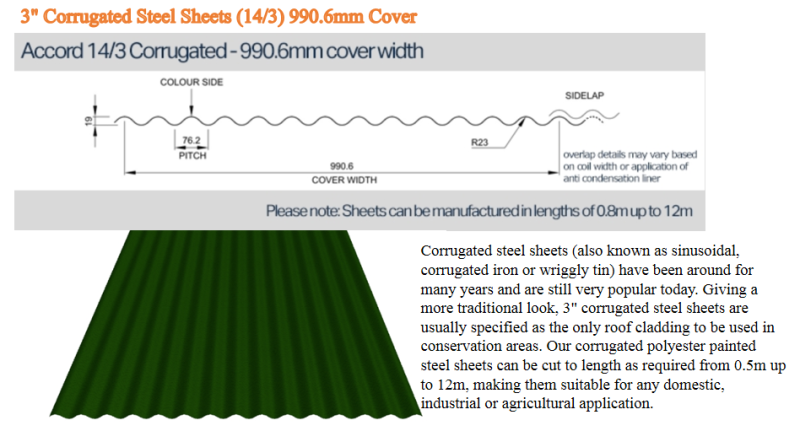

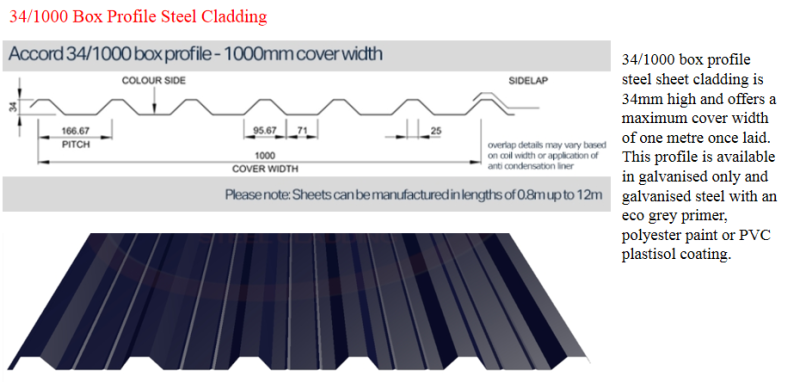

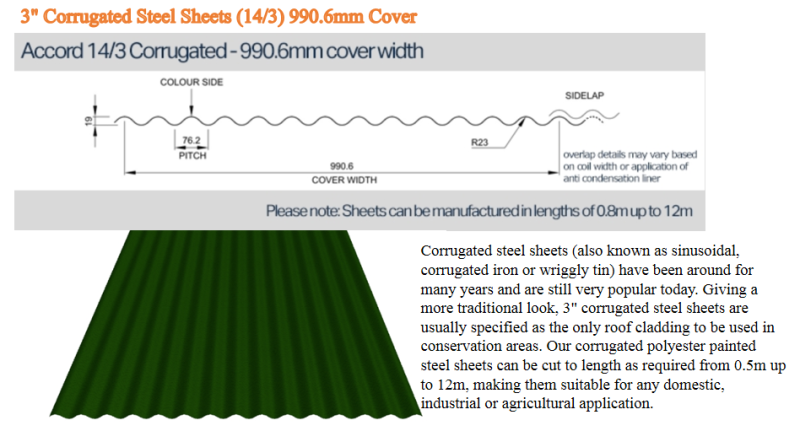

As these roof sheets are typically used on garden sheds, livestock buildings, and commercial warehouses we have made them available in the two most popular profiles

for these applications. You are, therefore, able to buy both corrugated and box profile sheets with an integrated anti-condensation membrane.

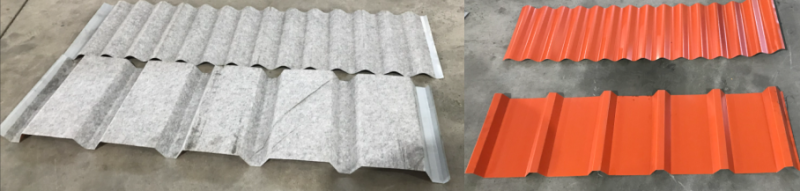

Compared with the normal PPGI, we add one more layer of felt under it. Here are some two popular of corrugated and box profile sheets for your reference.

But we can customize any kind of drawing profile based on your needs.

Felt information:

Felt information:

It is a new type of needle punched polyester non-woven fabric, produced by amending processing and special technology. From the production processing, the technical

requirements are much higher than the ordinary non-woven fabric; At the same time, from the quality of view, it also has the functional characteristics that other non-woven

fabrics do not have, with high moisture absorption, strong drainage and high flame retardant.

Anti-Condensation Roofing Sheets rolling forming machine

Machine working process

Machine working process:

Uncoiling → Feeding material into machine by device→Roll forming → Auto cutting →Products receiving table

|

Item |

Description of Item |

Unit |

Quantity |

|

1 |

5T manual decoiler |

set |

1 |

|

2 |

Main roll forming machine. With filming device |

set |

1 |

|

3 |

PLC control station |

set |

1 |

|

4 |

Hydraulic oil station |

set |

1 |

|

5 |

Product receiving table |

set |

1 |

Felt Coil width: 1250mm

Structure: Steel channel welded for the basic frame

Usage:Remove the plastic film of the felt,and glue the felt and steel plate together

Compared with normal PPGT roofing sheet machine, Anti-Condensation Roofing Sheets rolling forming machine with the following features:

1. It can support both normal PPGI, and PPGI with felt.

2. It is strong in shaft, big in rollers and have more rolling stations.

3. Use separated molding rolling process.

4. The profile made by such machine no scratching, no bending.

More details checking from the following pictures:

5.Leveling part with the stainless rollers and with the manual cutter.

6 The motor with brake and then it can save energy and protect the rollers. You can let one layer working.

As to the shearing, strong cutter holder and thick cutter for shearing more powerful and more longer time to use.

Anti-Condensation Roofing Sheets made by this machine:

Anti-Condensation Roofing Sheets made by this machine: